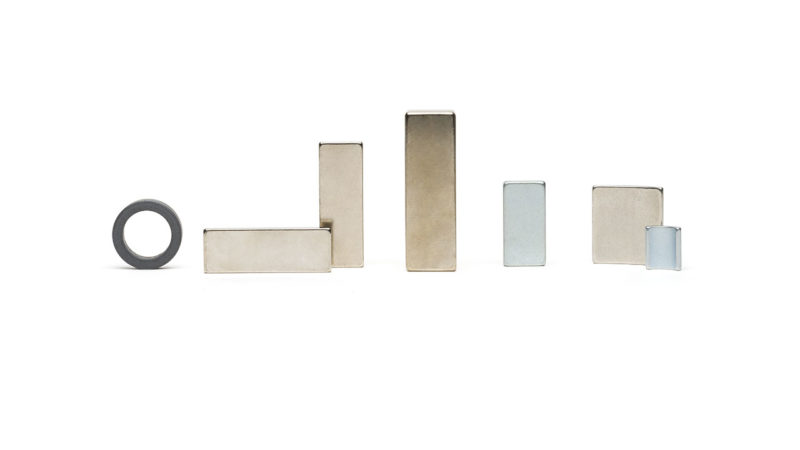

Permanent magnets

In common asynchronous motors, the rotor current is induced by the electromagnetic field generated by the stator. In this way, the rotor and stator produce two opposite electromagnetic fields, the interaction of which generates motion. However, the rotation speed remains almost constant during this process. Additionally, rotor currents generally result in leaks that decrease the performance of the machine.

To overcome these inefficiencies of the traditional copper-wound electric motor, permanent magnets were introduced that cause the rotor to move without the need for induced currents. This feature makes electric machines more efficient, allows their speed of rotation to be controlled and improves the torque at low RPM, given that there is no gearbox.

The main advantages of using permanent magnets are:

- efficiency

- energy saving

- direct coupling

- With Miotti you spend the right amount for a product that meets your requirements

Magnet manufacturers provide quality control that starts with the semi-finished blocks. Subsequent machining of the block to obtain the finished piece alters the performance of the magnets.

Miotti is able to measure performance parameters of the finished product and to inform the customer about the actual performance of the component that he is about to order and at the same time point him to the type of product that best suits his needs.

Neodymium Iron Boron Magnets (NdFeb)

Samarium Cobalt Magnets (SmCo)

Ferrite Magnets